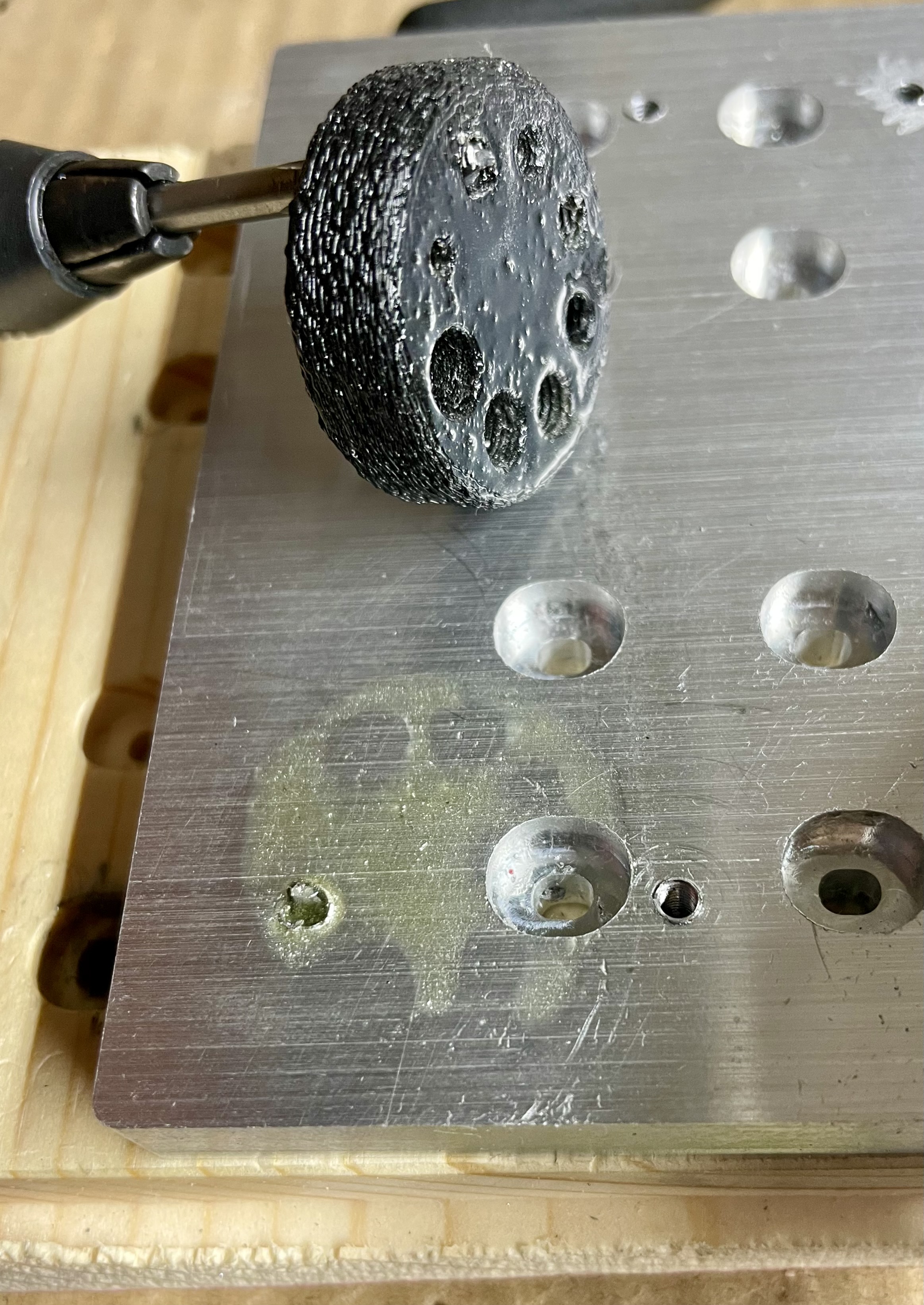

Why I hate manual tapping

The whole POINT of a CNC machine – a COMPUTER NUMERICALLY CONTROLLED machine is to program a machine to do the work for you! The MilkCr8 requires a number of bolts to be screwed into both aluminum and steel, and to be able to screw the bolts, you need some threads. One way to make those threads is to tap them. What that means is to drill (or bore) holes that are a little bit narrower in diameter than the final hole. Then you follow the drill (or boring end mill) with a tap. The tap cuts threads into the metal. Tapping can be slow going, and requires lubrication. Also, the taps can break off, pretty much eliminating that particular hole from use. Break too many taps and you might have to trash the whole piece. Also, and this might be just the tap set I have, The tap handle would often slip when trying to turn the tap. I lost a lot of time to this effort!