Dust Extraction - CNC is not a white glove experience

I have a few years experience with 3D printing. As an additive manufacturing technique, 3D printing is a clean and relatively quiet process involving heating up and extruding thin lines of plastic layer upon layer upon layer.

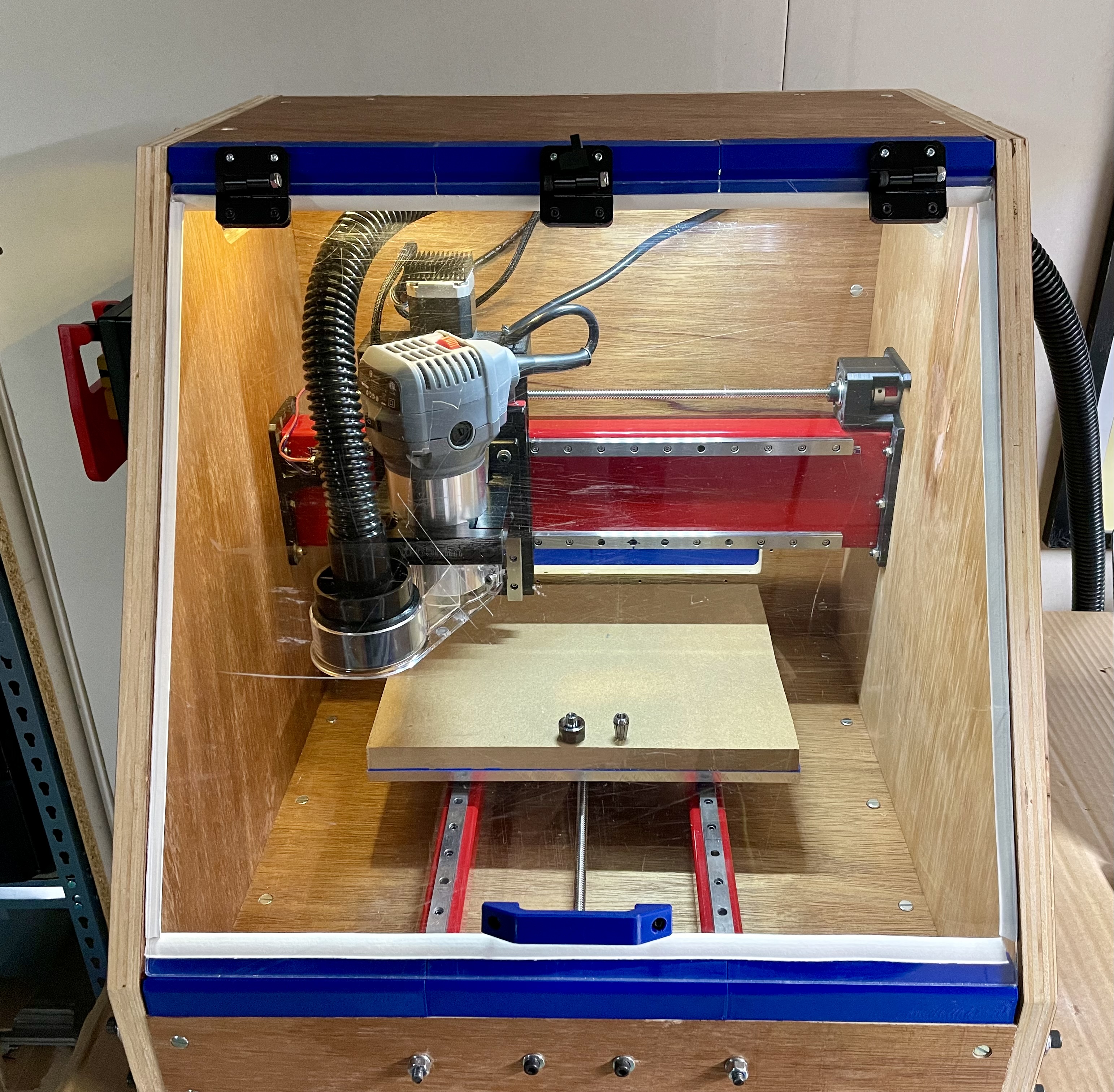

CNC milling is a subtractive process. A cutting device removes material from a piece of stock to reveal the intended object. The cutting is not a quiet process. Along with noise, the removal process creates sawdust, or chips of the removed material. Unless you want your MilkCr8 to be full of chips and/or sawdust all the time, it’s best to setup a system to remove sawdust/chips as you are machining.

Following the lead of @DreadMakerAdam, I purchased a Sweepy 2.0 from Carbide3D.

While there are all sorts of 3D printed options, this kit was clean and simple, and got high marks from Adam amd others.

For a hose, I purchased this 10 foot 1-3/16” O.D. hose. Fulton Hose Kit.

The hose fits through the MilkCr8 handle opening, which was slick, in that I didn’t have to cut an additional hole in the case. The hose did need an adapter to fit the Sweepy, but that was quick work in CAD and on my RailCore 3D printer.

The other end of the hose conveniently fit the inlet of my ShopVac.

In addition to the house, I also added some weatherstripping around the door to help keep chips (and noise) inside the MilkCr8. The dust/chips extraction works incredibly well, with the only downside that viewing the cutting action is a bit limited.