Why Build a MilkCr8 CNC?

It all started with quadcopters.

Back in 2014, I started down the path of the RC quadcopter hobby. By 2015 I realized that I often wanted small parts to enchance my quads. I soon figured out that 3D printers had seriously decreased in price since I had last looked at them. By Christmas I was the having a blast building a low-cost delta kit printer. Man. I learned a lot! But fall 2016 I was building my second printer – a much better quality kit from Czechia. About this time I realized I was much less interested in RC Quads than I was in 3D printing. By 2018, I was onto building my 4th printer. This printer was bigger and faster and also had exquisite layer stacking for higher quality prints - something I never achieved with my previous printers. Over time, the community developed some aluminum replacement parts for parts that were initially 3D printed. This allowed the printer to be more rigid, which allowed me to print faster without losing quality.

Say… these parts don’t look that difficult to create. I wonder if I could do that?

Thus – my interest in CNC machining was born.

The first machine that really caught my eye was the PrintNC

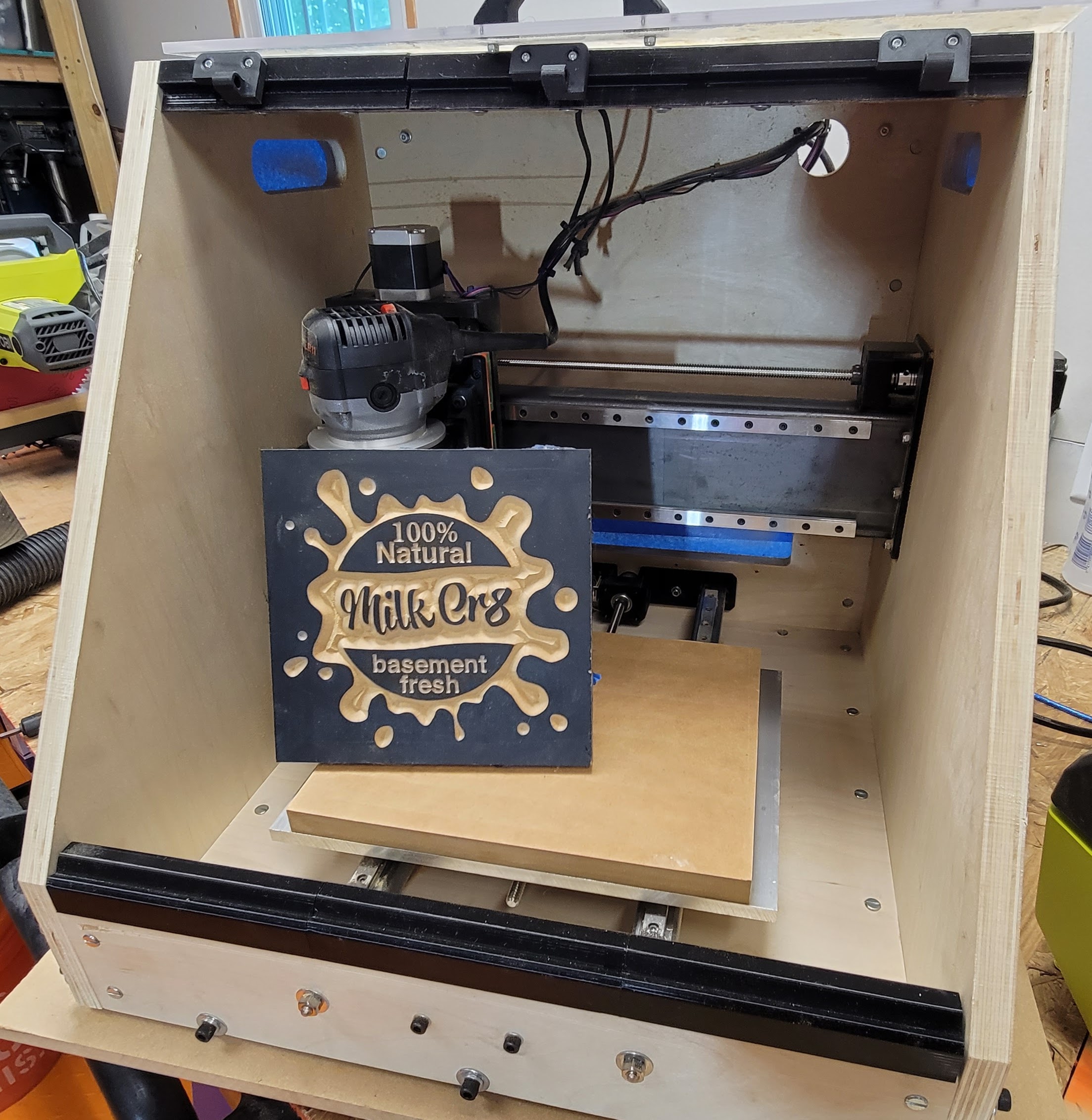

The PrintNC was exciting to me because it was rigid and easy to build with no fancy tools. The community around the PrintNC was healthy and growing. Unfortunately, it turns out the PrintNC was really too large for my space, so I kept looking. A few months later I found out that Joe from MakersOnTap Podcast was designing a smaller, enclosed CNC. I followed his progress through multiple revisions. He was also aware of the PrintNC and some of the movement areas are very similar. The MilkCr8 was something I could see myself building. I could also see it fitting into my basement. :)

Joe set out to design a rigid machine that could cleanly cut aluminum. He also designed the MilkCr8 to be easily built, using some 3D printed components that could be upgraded to aluminum (machined on the MilkCr8 itself) once the machine was built! True RepRap fashion!

So – once the BOM was set – I started planning my parts orders.

To be continued…

Image graciously borrowed from @adammhaile